Dantzig-Wolfe decomposition: combining sequential and parallel solving

Topics covered in this section:

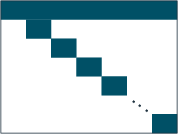

Dantzig-Wolfe decomposition (see [Teb01] for further detail) is a solution method for problems where, if a relatively small number of constraints were removed, the problem would fall apart into a number of independent problems. This means, it is possible to re-order the rows and columns of the constraint matrix as shown in Figure Coeffcient matrix with primal block angular structure, where non-zero coefficients only occur within the gray shaded areas. Such a primal block angular structure may become immediately apparent by visualizing a problem matrix. However, in most cases it will be necessary to re-organize the constraint definitions, grouping them by common index (sub)sets such as time periods, products, plant locations, and so on.

Figure 7: Coeffcient matrix with primal block angular structure

The constraints (including the objective function) involving variables of several or all subproblems are referred to as global constraints (also: common or linking constraints). These constraints are used to form the main problem. The individual blocks on the diagonal of the coefficient matrix are solved as pricing subproblems, coordinated by the main problem. By solving the main problem we obtain a solution to the original problem. Since the main problem has a large number of variables (defined by the set of basic feasible solutions and unbounded directions of the pricing problems), we work with a restricted main problem over a small subset of the variables. The variables to enter the active set of variables of the restricted main problem are determined by solving the pricing subproblems. With objective functions for the pricing problems that are based on the dual values of the restricted main problem we can obtain that the objective function value at each extreme point is the reduced cost (or price) of the variable of the main problem associated with the extreme point.

For maximization problems, solving the modified pricing problems generates basic feasible solutions of maximum reduced cost. If the objective value at an extreme point is positive, then the associated main problem variable is added to the main problem; if the minimum objective value over all extreme points is negative, then no main problem variable exists to improve the current main problem solution.

The computational advantage of Dantzig-Wolfe decomposition arises from performing a significant amount of the computational work in the pricing problems that are roughly an order of magnitude smaller than the original problem and thus easier to solve. An aspect of the method that is of interest in the context of this paper is that the subproblems are independent of each other, and may therefore be solved concurrently.

A potential drawback of the decomposition approach is the huge size of the main problem, it has many more variables—though fewer constraints—than the original problem. In general it is not required to generate all variables explicitly but since the feasible region of the main problem is more complex than that of the original problem, the solution path may be longer. Furthermore, numerical problems may occur through the dynamic generation of variables of the main problem.

Many factors may influence the performance of a decomposition approach, so for a particular application computational experiments will be required to find out whether this solution method is suitable. Such tests may include different ways of decomposing a given problem. As a general rule for the definition of a problem decomposition, one should aim for few global constraints since it is important to be able to (re)solve the main problem quickly. In addition, the pricing problems should be constructed in such a way that they are well formed problems in their own right to avoid computational problems due to degeneracy.

Example problem: multi-item, multi-period production planning

The company Coco has two plants that can produce two types of cocoa powder. The first factory has a total capacity of 400 tons per month and the second of 500 tons per month. The marketing department has provided estimations for the maximum amount of every product that may be sold in each of the next four months, and also the expected sales prices. Several raw materials are used in the production with known raw material requirements per ton of finished products. Finished products and raw material may be stored at the factories from one tim period to the next, incurring a given cost per ton and per time period. The raw material storage capacity at the factories is limited to 300 tons. How should the two plants be operated during the planning period to maximize the total profit?

Original model

Let PRODS be the set of finished products, FACT the set of factories, RAW the set of raw materials, and PERIODS={1,...,NT} the set of time periods under consideration.

We define decision variables makepft representing the quantity of product p made at factory f during time period t. Furthermore, to model the transition from one time period to the next and to account for the different types of cost incurred, we need several other sets of variables: sellpft, the amount of product p sold at factory f in period t; buyrft the amount of raw material r bought at f in t; and finally pstockpft and rstockrft (both defined for t=1,...,NT+1) respectively the amount of product and raw material held in stock at factory f at the beginning of period t.

Let further MXSELLpt be the maximum sales quantity of product p in period t, MXMAKEf the capacity limit of factory f, and MXRSTOCK the raw material storage capacity.

Let IPSTOCKpf be the quantity of product p initially held in stock at factory f and IRSTOCKrf the initial stock level of raw material r. We denote by CPSTOCK and CRSTOCK respectively the unit cost for storing finished product and raw material.

The objective function of maximizing the total profit is to maximize the sales revenues (REVp), minus the cost of production (CMAKEpf), buying raw material (CBUYrt), and storing finished products and raw material.

| ∑ |

| p ∈ PRODS |

| ∑ |

| f ∈ FACT |

| ∑ |

| t ∈ PERIODS |

-

| ∑ |

| p ∈ PRODS |

| ∑ |

| f ∈ FACT |

| ∑ |

| t ∈ PERIODS |

| ∑ |

| r ∈ RAW |

| ∑ |

| f ∈ FACT |

| ∑ |

| t ∈ PERIODS |

-

| ∑ |

| p ∈ PRODS |

| ∑ |

| f ∈ FACT |

| NT+1 |

| ∑ |

| t =2 |

| ∑ |

| r ∈ RAW |

| ∑ |

| f ∈ FACT |

| NT+1 |

| ∑ |

| t =2 |

The possibility to store products between time periods gives rise to three sets of constraints: the inventory balance constraints for finished products (PBalpft) and for raw material (RBalrft), and the limit on the raw material storage capacity (MxRStockft). The stock pstockp,f,t+1 of product p at the beginning of t+1 is given by the stock at the beginning of t plus the production in t reduced by the amount sold on t. The stock rstockr,f,t+1 of raw material r at the beginning of t+1 is given by the corresponding stock at the beginning of t plus the amount bought in t reduced by the quantity used in production during t.

∀ r ∈ RAW, ∀ f ∈ FACT, ∀ t ∈ PERIODS:

RBalrft:= rstockr,f,t+1 = rstockrft + buyrft -

| ∑ |

| p ∈ PRODS |

∀ f ∈ FACT, ∀ t ∈ {2,...,NT+1}: MxRStockft:=

| ∑ |

| r ∈ RAW |

We further have two sets of capacity constraints: the production capacity of the factories is limited (constraints MxMakeft) and we can only sell up to a given maximum amount of finished products per time period (constraints MxSellft).

Below the complete mathematical model is given. The initial stock levels (t=1) of finished products and raw material are fixed to the given values.

| ∑ |

| p ∈ PRODS |

| ∑ |

| f ∈ FACT |

| ∑ |

| t ∈ PERIODS |

-

| ∑ |

| p ∈ PRODS |

| ∑ |

| f ∈ FACT |

| ∑ |

| t ∈ PERIODS |

| ∑ |

| r ∈ RAW |

| ∑ |

| f ∈ FACT |

| ∑ |

| t ∈ PERIODS |

-

| ∑ |

| p ∈ PRODS |

| ∑ |

| f ∈ FACT |

| NT+1 |

| ∑ |

| t =2 |

| ∑ |

| r ∈ RAW |

| ∑ |

| f ∈ FACT |

| NT+1 |

| ∑ |

| t =2 |

∀ p ∈ PRODS, ∀ f ∈ FACT, ∀ t ∈ PERIODS: PBalpft:= pstockp,f,t+1 = pstockpft + makepft - sellpft

∀ r ∈ RAW, ∀ f ∈ FACT, ∀ t ∈ PERIODS:

RBalrft:= rstockr,f,t+1 = rstockrft + buyrft -

| ∑ |

| p ∈ PRODS |

∀ p ∈ PRODS, ∀ t ∈ PERIODS: MxSellpt:=

| ∑ |

| f ∈ FACT |

∀ f ∈ FACT, ∀ t ∈ PERIODS: MxMakeft:=

| ∑ |

| p ∈ PRODS |

∀ f ∈ FACT, ∀ t ∈ {2,...,NT+1}: MxRStockft:=

| ∑ |

| r ∈ RAW |

∀ p ∈ PRODS, ∀ f ∈ FACT: pstockpf1 = IPSTOCKpf

∀ r ∈ RAW, ∀ f ∈ FACT: rstockrf1 = IRSTOCKrf

∀ p ∈ PRODS, ∀ f ∈ FACT, ∀ t ∈ PERIODS: makepft≥ 0, sellpft≥ 0

∀ r ∈ RAW, ∀ f ∈ FACT, ∀ t ∈ PERIODS: buyrft ≥ 0

∀ p ∈ PRODS, ∀ f ∈ FACT, ∀ t ∈ {1,...,NT+1}: pstockpft ≥ 0

∀ r ∈ RAW, ∀ f ∈ FACT, ∀ t ∈ {1,...,NT+1}: rstockrft ≥ 0

Problem decomposition

We now decompose the problem described above according to production locations. Notice that this is not the only way of decomposing this problem: we may just as well choose a decomposition by products or by time periods. However, both of these choices result in a larger number of global constraints than the decomposition by factories, meaning that the main problem may become more difficult to solve.

For every factory f we obtain the following subproblem (including the sales limit constraints MxSell in the form of bounds in the submodels is not required, but may lead to better, that is, more exact or faster solutions).

| ∑ |

| p ∈ PRODS |

| ∑ |

| t ∈ PERIODS |

-

| ∑ |

| p ∈ PRODS |

| ∑ |

| t ∈ PERIODS |

| ∑ |

| r ∈ RAW |

| ∑ |

| t ∈ PERIODS |

-

| ∑ |

| p ∈ PRODS |

| NT+1 |

| ∑ |

| t =2 |

| ∑ |

| r ∈ RAW |

| NT+1 |

| ∑ |

| t =2 |

∀ p ∈ PRODS, ∀ t ∈ PERIODS: PBalpt:= pstockp,t+1 = pstockpt + makept - sellpt

∀ r ∈ RAW, ∀ t ∈ PERIODS: RBalrt:= rstockr,t+1 = rstockrt + buyrt -

| ∑ |

| p ∈ PRODS |

∀ t ∈ PERIODS: MxMaket:=

| ∑ |

| p ∈ PRODS |

∀ t ∈ {2,...,NT+1}: MxRStockt:=

| ∑ |

| r ∈ RAW |

∀ p ∈ PRODS, ∀ t ∈ PERIODS: MxSellpt:= sellpt ≤ MXSELLp

∀ p ∈ PRODS: pstockp1 = IPSTOCKp

∀ r ∈ RAW: rstockr1 = IRSTOCKr

∀ p ∈ PRODS, ∀ t ∈ PERIODS: makept≥ 0, sellpt≥ 0

∀ r ∈ RAW, ∀ t ∈ PERIODS: buyrt ≥ 0

∀ p ∈ PRODS, ∀ t ∈ {1,...,NT+1}: pstockpt ≥ 0

∀ r ∈ RAW, ∀ t ∈ {1,...,NT+1}: rstockrt ≥ 0

The main problem only contains a single set of global constraints, namely the sales limit constraints MxSell (for clarity's sake, the non-negativity constraints are left out here).

| ∑ |

| p ∈ PRODS |

| ∑ |

| f ∈ FACT |

| ∑ |

| t ∈ PERIODS |

-

| ∑ |

| p ∈ PRODS |

| ∑ |

| f ∈ FACT |

| ∑ |

| t ∈ PERIODS |

| ∑ |

| r ∈ RAW |

| ∑ |

| f ∈ FACT |

| ∑ |

| t ∈ PERIODS |

-

| ∑ |

| p ∈ PRODS |

| ∑ |

| f ∈ FACT |

| NT+1 |

| ∑ |

| t =2 |

| ∑ |

| r ∈ RAW |

| ∑ |

| f ∈ FACT |

| NT+1 |

| ∑ |

| t =2 |

∀ p ∈ PRODS, ∀ t ∈ PERIODS: MxSellpt:=

| ∑ |

| f ∈ FACT |

In the decomposition algorithm, the decision variables in the main problem are expressed via the solutions (proposals) generated by the subproblems, such as

| nPROPf |

| ∑ |

| k=1 |

where Prop_sellpftk stands for the solution value of variable sellpt in the kth proposal generated by subproblem f and Prop_costfk is the objective value this proposal. For every subproblem f we need to add a convexity constraint Convexf on the weightfk variables.

| ∑ |

| f ∈ FACT |

| nPROPf |

| ∑ |

| k=1 |

∀ p ∈ PRODS, ∀ t ∈ PERIODS: MxSellpt:=

| ∑ |

| f ∈ FACT |

| nPROPf |

| ∑ |

| k=1 |

∀ f ∈ FACT: Convexf:=

| nPROPf |

| ∑ |

| k=1 |

∀ f ∈ FACT, ∀ k ∈ 1,...,nPROPf: weightfk≥ 0

We shall refer to this problem as the modified main problem. Without going any further into technical detail we simply remark that a correspondence exists between the solution of the original problem and those of the modified main problem.

Implementation

The decomposition algorithm has several phases:

- Phase 1: generation of a set of proposals to obtain a feasible solution to the modified main problem.

- Phase 2: optimization of the modified main problem.

- Phase 3: calculate the solution to the original problem.

The suproblems solved in phases 1 and 2 take as their objective functions sums of the dual values from the modfied main problem. To avoid starting off with an empty main problem and hence random dual information that may be misleading we add a crash Phase 0 to our implementation that generates one proposal for each subproblem with the original objective function.

Main model

Below follows the body of the main model file. The definitions of the function bodies will be shown later in Section Main model subroutines.

model "Coco3 Main"

uses "mmxprs","mmjobs","mmsystem"

parameters

DATAFILE = "coco2.dat"

ALG = 0 ! 0: stop phase with 1st failed subpb.

! 1: stop when all subprob.s fail

end-parameters

forward procedure process_sub_result

forward procedure solve_main(phase:integer)

forward procedure process_main_result

forward function calc_solution:real

forward procedure print_solution

declarations

PHASE_0=2 ! Event codes sent to submodels

PHASE_1=3

PHASE_2=4

PHASE_3=5

EVENT_SOLVED=6 ! Event codes sent by submodels

EVENT_FAILED=7

EVENT_READY=8

NPROD, NFACT, NRAW, NT: integer

end-declarations

initializations from DATAFILE

NPROD NFACT NRAW NT

end-initializations

declarations

PRODS = 1..NPROD ! Range of products (p)

FACT = 1..NFACT ! factories (f)

RAW = 1..NRAW ! raw materials (r)

PERIODS = 1..NT ! time periods (t)

nIter: integer ! Iteration counter

nPROP: array(FACT) of integer ! Counters of proposals from subprob.s

end-declarations

!**** Main problem ****

declarations

MXSELL: array(PRODS,PERIODS) of real ! Max. amount of p that can be sold

excessS: mpvar ! Violation of sales/buying limits

weight: array(FACT,range) of mpvar ! weights for proposals

MxSell: array(PRODS,PERIODS) of linctr ! Sales limit constraints

Convex: array(FACT) of linctr ! Convexity constraints

Price_convex: array(FACT) of real ! Dual price on convexity constraints

Price_sell: array(PRODS,PERIODS) of real ! Dual price on sales limits

end-declarations

initializations from DATAFILE

MXSELL

end-initializations

!**** Submodels ****

declarations

submod: array(FACT) of Model ! One subproblem per factory

Stopped: set of integer

end-declarations

res:= compile("g","cocoSubF.mos") ! Compile the submodel file

forall(f in FACT) do ! Load & run one submodel per product

Price_convex(f):= 1

load(submod(f), "cocoSubF.bim")

submod(f).uid:= f

run(submod(f), "Factory=" + f + ",DATAFILE=" + DATAFILE)

wait ! Wait for child model to be ready

ev:=getnextevent

if ev.class=EVENT_END then

writeln_("Cannot start all necessary models - aborting")

exit(1)

end-if

end-do

!**** Phase 0: Crash ****

nIter:=1; finished:=false

writeln_("\nPHASE 0 -- Iteration ", nIter); fflush

forall(f in FACT) ! Start solving all submodels (Phase 1)

send(submod(f), PHASE_0, 0)

forall(f in FACT) do

wait ! Wait for child (termination) events

ev:= getnextevent

if getclass(ev)=EVENT_SOLVED then

process_sub_result ! Add new proposal to main problem

elif getclass(ev)=EVENT_FAILED then

finished:= true

end-if

end-do

if finished then

writeln_("Problem is infeasible")

exit(1)

end-if

solve_main(1) ! Solve the updated Ph. 1 main problem

process_main_result ! Store initial pricing data for submodels

!**** Phase 1: proposal generation (feasibility) ****

repeat

noimprove:= 0

nIter+=1

writeln_("\nPHASE 1 -- Iteration ", nIter); fflush

forall(f in FACT) ! Start solving all submodels (Phase 1)

send(submod(f), PHASE_1, Price_convex(f))

forall(f in FACT) do

wait ! Wait for child (termination) events

ev:= getnextevent

if getclass(ev)=EVENT_SOLVED then

process_sub_result ! Add new proposal to main problem

elif getclass(ev)=EVENT_FAILED then

noimprove += 1

end-if

end-do

if noimprove = NFACT then

writeln_("Problem is infeasible")

exit(2)

end-if

if ALG=0 and noimprove > 0 then

writeln_("No improvement by some subproblem(s)")

break

end-if

solve_main(1) ! Solve the updated Ph. 1 main problem

if getobjval>0.00001 then

process_main_result ! Store new pricing data for submodels

end-if

until getobjval <= 0.00001

!**** Phase 2: proposal generation (optimization) ****

writeln_("\n**** PHASE 2 ****")

finished:=false

repeat

solve_main(2) ! Solve Phase 2 main problem

process_main_result ! Store new pricing data for submodels

nIter+=1

writeln_("\nPHASE 2 -- Iteration ", nIter); fflush

forall(f in FACT) ! Start solving all submodels (Phase 2)

send(submod(f), PHASE_2, Price_convex(f))

forall(f in FACT) do

wait ! Wait for child (termination) events

ev:= getnextevent

if getclass(ev)=EVENT_SOLVED then

process_sub_result ! Add new proposal to main problem

elif getclass(ev)=EVENT_FAILED then

if ALG=0 then

finished:=true ! 1st submodel w/o prop. stops phase 2

else

Stopped += {ev.fromuid} ! Stop phase 2 only when no submodel

! generates a new proposal

end-if

end-if

end-do

if getsize(Stopped) = NFACT then finished:= true; end-if

until finished

solve_main(2) ! Re-solve main to integrate

! proposal(s) from last ph. 2 iteration

!**** Phase 3: solution to the original problem ****

writeln_("\n**** PHASE 3 ****")

forall(f in FACT) do

send(submod(f), PHASE_3, 0) ! Stop all submodels

wait

dropnextevent

end-do

writeln_("Total Profit=", calc_solution)

print_solution

end-model The initial declarations block of this model defines a certain number of event codes that are used to identify the messages sent between the controlling (main) model and its child (sub)models. The same declarations need to be repeated in the child models.

Single factory model

The model file cocoSubF.mos with the definition of the subproblems has the following contents.

model "Coco Subproblem (factory based decomp.)"

uses "mmxprs", "mmjobs"

parameters

Factory = 0

TOL = 0.00001

DATAFILE = "coco3.dat"

end-parameters

forward procedure process_solution

declarations

PHASE_0=2 ! Event codes sent to submodels

PHASE_1=3

PHASE_2=4

PHASE_3=5

EVENT_SOLVED=6 ! Event codes sent by submodels

EVENT_FAILED=7

EVENT_READY=8

NPROD, NFACT, NRAW, NT: integer

end-declarations

send(EVENT_READY,0) ! Model is ready (= running)

initializations from DATAFILE

NPROD NFACT NRAW NT

end-initializations

declarations

PRODS = 1..NPROD ! Range of products (p)

FACT = 1..NFACT ! factories (f)

RAW = 1..NRAW ! raw materials (r)

PERIODS = 1..NT ! time periods (t)

REV: array(PRODS,PERIODS) of real ! Unit selling price of products

CMAKE: array(PRODS,FACT) of real ! Unit cost to make product p

! at factory f

CBUY: array(RAW,PERIODS) of real ! Unit cost to buy raw materials

REQ: array(PRODS,RAW) of real ! Requirement by unit of product p

! for raw material r

MXSELL: array(PRODS,PERIODS) of real ! Max. amount of p that can be sold

MXMAKE: array(FACT) of real ! Max. amount factory f can make

! over all products

IPSTOCK: array(PRODS,FACT) of real ! Initial product stock levels

IRSTOCK: array(RAW,FACT) of real ! Initial raw material stock levels

CPSTOCK: real ! Unit cost to store any product p

CRSTOCK: real ! Unit cost to store any raw mat. r

MXRSTOCK: real ! Raw material storage capacity

make: array(PRODS,PERIODS) of mpvar ! Amount of products made at factory

sell: array(PRODS,PERIODS) of mpvar ! Amount of product sold from factory

buy: array(RAW,PERIODS) of mpvar ! Amount of raw material bought

pstock: array(PRODS,1..NT+1) of mpvar ! Product stock levels at start

! of period t

rstock: array(RAW,1..NT+1) of mpvar ! Raw material stock levels

! at start of period t

sol_make: array(PRODS,PERIODS) of real ! Amount of products made

sol_sell: array(PRODS,PERIODS) of real ! Amount of product sold

sol_buy: array(RAW,PERIODS) of real ! Amount of raw mat. bought

sol_pstock: array(PRODS,1..NT+1) of real ! Product stock levels

sol_rstock: array(RAW,1..NT+1) of real ! Raw mat. stock levels

Profit: linctr ! Profit of proposal

Price_sell: array(PRODS,PERIODS) of real ! Dual price on sales limits

end-declarations

initializations from DATAFILE

CMAKE REV CBUY REQ MXSELL MXMAKE

IPSTOCK IRSTOCK MXRSTOCK CPSTOCK CRSTOCK

end-initializations

! Product stock balance

forall(p in PRODS,t in PERIODS)

PBal(p,t):= pstock(p,t+1) = pstock(p,t) + make(p,t) - sell(p,t)

! Raw material stock balance

forall(r in RAW,t in PERIODS)

RBal(r,t):= rstock(r,t+1) =

rstock(r,t) + buy(r,t) - sum(p in PRODS) REQ(p,r)*make(p,t)

! Capacity limit

forall(t in PERIODS)

MxMake(t):= sum(p in PRODS) make(p,t) <= MXMAKE(Factory)

! Limit on the amount of prod. p to be sold

forall(p in PRODS,t in PERIODS) sell(p,t) <= MXSELL(p,t)

! Raw material stock limit

forall(t in 2..NT+1)

MxRStock(t):= sum(r in RAW) rstock(r,t) <= MXRSTOCK

! Initial product and raw material stock levels

forall(p in PRODS) pstock(p,1) = IPSTOCK(p,Factory)

forall(r in RAW) rstock(r,1) = IRSTOCK(r,Factory)

! Total profit

Profit:=

sum(p in PRODS,t in PERIODS) REV(p,t) * sell(p,t) - ! revenue

sum(p in PRODS,t in PERIODS) CMAKE(p,Factory) * make(p,t) - ! prod. cost

sum(r in RAW,t in PERIODS) CBUY(r,t) * buy(r,t) - ! raw mat.

sum(p in PRODS,t in 2..NT+1) CPSTOCK * pstock(p,t) - ! p storage

sum(r in RAW,t in 2..NT+1) CRSTOCK * rstock(r,t) ! r storage

! (Re)solve this model until it is stopped by event "PHASE_3"

repeat

wait

ev:= getnextevent

Phase:= getclass(ev)

if Phase=PHASE_3 then ! Stop the execution of this model

break

end-if

Price_convex:= getvalue(ev) ! Get new pricing data

if Phase<>PHASE_0 then

initializations from "bin:shmem:pricedata"

Price_sell

end-initializations

end-if

! (Re)solve this model

if Phase=PHASE_0 then

maximize(Profit)

elif Phase=PHASE_1 then

maximize(sum(p in PRODS,t in PERIODS) Price_sell(p,t)*sell(p,t) + Price_convex)

else ! PHASE 2

maximize(

Profit - sum(p in PRODS,t in PERIODS) Price_sell(p,t)*sell(p,t) -

Price_convex)

end-if

writeln_("Factory ", Factory, " - Obj: ", getobjval,

" Profit: ", getsol(Profit), " Price_sell: ",

getsol(sum(p in PRODS,t in PERIODS) Price_sell(p,t)*sell(p,t) ),

" Price_convex: ", Price_convex)

fflush

if getobjval > TOL then ! Solution found: send values to parent

process_solution

elif getobjval <= TOL then ! Problem is infeasible (Phase 0/1) or

send(EVENT_FAILED,0) ! no improved solution found (Phase 2)

else

send(EVENT_READY,0)

end-if

until false

!-----------------------------------------------------------

! Process solution data

procedure process_solution

forall(p in PRODS,t in PERIODS) do

sol_make(p,t):= getsol(make(p,t))

sol_sell(p,t):= getsol(sell(p,t))

end-do

forall(r in RAW,t in PERIODS) sol_buy(r,t):= getsol(buy(r,t))

forall(p in PRODS,t in 1..NT+1) sol_pstock(p,t):= getsol(pstock(p,t))

forall(r in RAW,t in 1..NT+1) sol_rstock(r,t):= getsol(rstock(r,t))

Prop_cost:= getsol(Profit)

send(EVENT_SOLVED,0)

initializations to "mempipe:noindex,sol"

Factory

sol_make sol_sell sol_buy sol_pstock sol_rstock

Prop_cost

end-initializations

end-procedure

end-model The child models are re-solved until they receive the PHASE_3 code. At every iteration they write their solution values to memory so that these can be processed by the parent model.

Main model subroutines

The following three subroutines are defined in the main model to recover the solutions produced by the subproblems (process_sub_result), re-solve the main problem (solve_main), and communicate the solution of the main problem to the child models (process_main_result).

declarations

Prop_make: array(PRODS,FACT,PERIODS,range) of real ! Amount of products made

Prop_sell: array(PRODS,FACT,PERIODS,range) of real ! Amount of product sold

Prop_buy: array(RAW,FACT,PERIODS,range) of real ! Amount of raw mat. bought

Prop_pstock: array(PRODS,FACT,1..NT+1,range) of real ! Product stock levels

Prop_rstock: array(RAW,FACT,1..NT+1,range) of real ! Raw mat. stock levels

Prop_cost: array(FACT,range) of real ! Cost/profit of each proposal

end-declarations

procedure process_sub_result

declarations

f: integer ! Factory index

! Solution values of the proposal:

sol_make: array(PRODS,PERIODS) of real ! Amount of products made

sol_sell: array(PRODS,PERIODS) of real ! Amount of product sold

sol_buy: array(RAW,PERIODS) of real ! Amount of raw mat. bought

sol_pstock: array(PRODS,1..NT+1) of real ! Product stock levels

sol_rstock: array(RAW,1..NT+1) of real ! Raw mat. stock levels

pc: real ! Cost of the proposal

end-declarations

! Read proposal data from memory

initializations from "mempipe:noindex,sol"

f as "Factory"

sol_make sol_sell sol_buy sol_pstock sol_rstock

pc as "Prop_cost"

end-initializations

! Add the new proposal to the main problem

nPROP(f)+=1

create(weight(f,nPROP(f)))

forall(p in PRODS,t in PERIODS) do

Prop_make(p,f,t,nPROP(f)):= sol_make(p,t)

Prop_sell(p,f,t,nPROP(f)):= sol_sell(p,t)

end-do

forall(r in RAW,t in PERIODS) Prop_buy(r,f,t,nPROP(f)):= sol_buy(r,t)

forall(p in PRODS,t in 1..NT+1) Prop_pstock(p,f,t,nPROP(f)):= sol_pstock(p,t)

forall(r in RAW,t in 1..NT+1) Prop_rstock(r,f,t,nPROP(f)):= sol_rstock(r,t)

Prop_cost(f,nPROP(f)):= pc

writeln_("Sol. for factory ", f, ":\n make: ", sol_make, "\n sell: ",

sol_sell, "\n buy: ", sol_buy, "\n pstock: ", sol_pstock,

"\n rstock: ", sol_rstock)

end-procedure

!-----------------------------------------------------------

procedure solve_main(phase: integer)

forall(f in FACT)

Convex(f):= sum (k in 1..nPROP(f)) weight(f,k) = 1

if phase=1 then

forall(p in PRODS,t in PERIODS)

MxSell(p,t):=

sum(f in FACT,k in 1..nPROP(f)) Prop_sell(p,f,t,k)*weight(f,k) -

excessS <= MXSELL(p,t)

minimize(excessS)

else

forall(p in PRODS,t in PERIODS)

MxSell(p,t):=

sum(f in FACT,k in 1..nPROP(f)) Prop_sell(p,f,t,k)*weight(f,k) <=

MXSELL(p,t)

maximize(sum(f in FACT, k in 1..nPROP(f)) Prop_cost(f,k) * weight(f,k))

end-if

writeln_("Main problem objective: ", getobjval)

write_(" Weights:")

forall(f in FACT,k in 1..nPROP(f)) write(" ", getsol(weight(f,k)))

writeln

end-procedure

!-----------------------------------------------------------

procedure process_main_result

forall(p in PRODS,t in PERIODS) Price_sell(p,t):=getdual(MxSell(p,t))

forall(f in FACT) Price_convex(f):=getdual(Convex(f))

initializations to "bin:shmem:pricedata"

Price_sell

end-initializations

end-procedure Finally, the main model is completed by two subroutines for calculating the solution to the original problem (calc_solution), Phase 3 of the decomposition algorithm, and printing out the solution (print_solution). The solution to the original problem is obtained from the solution values of the modfied main problem and the proposals generated by the subproblems.

declarations

REV: array(PRODS,PERIODS) of real ! Unit selling price of products

CMAKE: array(PRODS,FACT) of real ! Unit cost to make product p

! at factory f

CBUY: array(RAW,PERIODS) of real ! Unit cost to buy raw materials

COPEN: array(FACT) of real ! Fixed cost of factory f being

! open for one period

CPSTOCK: real ! Unit cost to store any product p

CRSTOCK: real ! Unit cost to store any raw mat. r

Sol_make: array(PRODS,FACT,PERIODS) of real ! Solution value (products made)

Sol_sell: array(PRODS,FACT,PERIODS) of real ! Solution value (product sold)

Sol_buy: array(RAW,FACT,PERIODS) of real ! Solution value (raw mat. bought)

Sol_pstock: array(PRODS,FACT,1..NT+1) of real ! Sol. value (prod. stock)

Sol_rstock: array(RAW,FACT,1..NT+1) of real ! Sol. value (raw mat. stock)

end-declarations

initializations from DATAFILE

CMAKE REV CBUY CPSTOCK CRSTOCK COPEN

end-initializations

function calc_solution: real

forall(p in PRODS,f in FACT,t in PERIODS) do

Sol_sell(p,f,t):=

sum(k in 1..nPROP(f)) Prop_sell(p,f,t,k) * getsol(weight(f,k))

Sol_make(p,f,t):=

sum(k in 1..nPROP(f)) Prop_make(p,f,t,k) * getsol(weight(f,k))

end-do

forall(r in RAW,f in FACT,t in PERIODS) Sol_buy(r,f,t):=

sum(k in 1..nPROP(f)) Prop_buy(r,f,t,k) * getsol(weight(f,k))

forall(p in PRODS,f in FACT,t in 1..NT+1) Sol_pstock(p,f,t):=

sum(k in 1..nPROP(f)) Prop_pstock(p,f,t,k) * getsol(weight(f,k))

forall(r in RAW,f in FACT,t in 1..NT+1) Sol_rstock(r,f,t):=

sum(k in 1..nPROP(f)) Prop_rstock(r,f,t,k) * getsol(weight(f,k))

returned:=

sum(p in PRODS,f in FACT,t in PERIODS) REV(p,t) * Sol_sell(p,f,t) -

sum(p in PRODS,f in FACT,t in PERIODS) CMAKE(p,f) * Sol_make(p,f,t) -

sum(r in RAW,f in FACT,t in PERIODS) CBUY(r,t) * Sol_buy(r,f,t) -

sum(p in PRODS,f in FACT,t in 2..NT+1) CPSTOCK * Sol_pstock(p,f,t) -

sum(r in RAW,f in FACT,t in 2..NT+1) CRSTOCK * Sol_rstock(r,f,t)

end-function

!-----------------------------------------------------------

procedure print_solution

writeln_("Finished products:")

forall(f in FACT) do

writeln_("Factory ", f, ":")

forall(p in PRODS) do

write(" ", p, ": ")

forall(t in PERIODS) write(strfmt(Sol_make(p,f,t),6,1), "(",

strfmt(Sol_pstock(p,f,t+1),5,1), ")")

writeln

end-do

end-do

writeln_("Raw material:")

forall(f in FACT) do

writeln_("Factory ", f, ":")

forall(r in RAW) do

write(" ", r, ": ")

forall(t in PERIODS) write(strfmt(Sol_buy(r,f,t),6,1), "(",

strfmt(Sol_rstock(r,f,t+1),5,1), ")")

writeln

end-do

end-do

writeln_("Sales:")

forall(f in FACT) do

writeln_("Factory ", f, ":")

forall(p in PRODS) do

write(" ", p, ": ")

forall(t in PERIODS) write(strfmt(Sol_sell(p,f,t),4))

writeln

end-do

end-do

writeln_("\nComputation time: ", gettime)

end-procedure Results

For the test cases that have been tried the solutions produced by our decomposition algorithm are close to the optimal solution, but the latter is not always reached. The reason behind this is that the decomposition algorithm is a sequence of iterations that may accumulate errors at different levels—lowering the tolerances used as stopping criterion in the submodels most of the time does not improve the solution. However, the configuration of the decomposition algorithm itself shows some impact on the solution: in phases 1 and 2 one may choose, for instance, to stop once the first submodel returns no improvement or continue until no more proposals are generated. Generating more proposals sometimes helps finding a better solution, but it also increases the number of times (sub)problems are solved and hence prolongates the solving time.

© 2001-2025 Fair Isaac Corporation. All rights reserved. This documentation is the property of Fair Isaac Corporation (“FICO”). Receipt or possession of this documentation does not convey rights to disclose, reproduce, make derivative works, use, or allow others to use it except solely for internal evaluation purposes to determine whether to purchase a license to the software described in this documentation, or as otherwise set forth in a written software license agreement between you and FICO (or a FICO affiliate). Use of this documentation and the software described in it must conform strictly to the foregoing permitted uses, and no other use is permitted.